How to Build a Meat Curing Chamber for under $200

NEW: Check out the video on youtube. The 30-minute video walks you through how to use this entire setup!

My meat curing chamber is a converted wine cooler in my basement. The purpose of the meat curing chamber is to create an environment in which to cure meats that were consistently 70% relative humidity at 65°F, without spending a lot of money or creating some sort of giant that I couldn’t move easily.

A quick search on craigslist.org yielded this little beauty. A Danby Millennium Home Wine Cooler. The asking price of $100 was a third of its sticker price. The original owner had kept it nice and clean. Upon inspection, I found it to be super cold inside and running quietly when they showed it. I couldn’t resist.

A quick scan of the user’s manual showed that the range of this device was 42° – 65°F, so I knew I’d have to replace the thermostat. While I was at it, I figured I’d wire in a hygrostat, too, to keep the humidity in check. These digital thermostats are actually pretty cool. They run on 120V. They tap the hot circuit to run and then offer a probe and a relay. My challenge was to wire them in parallel to provide switched power to the compressor and also be able to run a humidifier or maybe a dehumidifier, but that would come later, once I had some idea of what the humidity would be under normal operation.

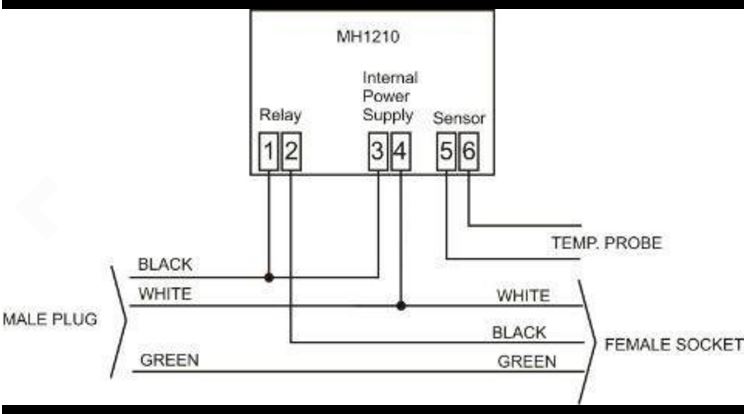

Here are the basic inputs and outputs on the digital controller.

I used some heavy-duty plastic Velcro-type mounting tabs to hold them to the roof of the fridge. I had some trouble finding good, clear, instructions on how to program the controls once I got them installed. Here are some links to the pdfs of the manuals. These were the best ones that I could find:

Unlike everybody else in the world, I need a dehumidifier in my cure box. You can see the moisture on the walls. I found a tiny closet-sized Thermo-Electric Dehumidifier on Amazon.com. With a little brute strength and some sharp tools, I was able to make it even smaller. It has some condenser fins on the back of it that conveniently drip right into the drain on the back of the fridge. The drain empties into a pan under the fridge that allows the condensate to evaporate to the outside room. I’m still working on the mounting of the dehumidifier. Right now, it’s hanging with some butchers’ twine. Not great, but functional. There’s also a lot of exposed 110V circuitry but we’re not even talking about that right now. In retrospect, I would have kept the dehumidifier intact and plugged it into a 3 Pins Power Socket Plug.

The Meat Curing Chamber is a success! The digital controls are visible through the door of the old wine cooler–as are the salame! The controls work nicely with the compressor. The STC-1000 even has a programmable delay to keep the compressor from cycling on and off too quickly, thus extending its life. There’s usually a couple of ounces of water in the condensate evaporator tray. It’s right on top of the compressor, utilizing its heat to drive the evaporation.

NEW: Check out the video on youtube

2019 UPDATE: Look at this cool new controller from INKBIRD:

Nice job! Did a similar build myself recently, using the same humidity controller, but a slightly different temp controller. Mine only does either heating OR cooling, I think the STC1000 does both. I’ll have to check back to see how yours is going 🙂

Indeed it does!

Pingback: How to Salt Cure and Air Dry a Homemade Coppa - Better Done Yourself

Im looking into building one of these my self and this was the best way I’ve seen so far nice and compact. My question is did you need the dehumidifier because you had it set at 65 and it naturally got that humid in there at the 65 degrees ? and did you have to by pass anything out of the ordinary when doing this with the wiring? thanks for your time!

Or is it that you used a wine fridge rather than a traditional refrigerator? there is a note on using wine fridges here: http://curedmeats.blogspot.com/2012/08/lets-talk-curing-chambers.html

Great post – I have been doing some home curing in an unmodified wine fridge, to some success, but I know I need to fix the humidity issue. I was curious why you replaced the thermostat – isn’t 50-60F the ideal temp?

Also, how hard do you think it would be for someone with very minimal electrical experience to wire in a dehumidifier/hygrostat? The link to the wiring schematic didn’t work – could you send me a copy? thanks!!

Neil

Wondering if I can build a smoker out of a glass wine fridge using electric burner?

I’ve been thinking about this. I don’t think it would be a good idea because this insides of such are made of cold temp plastic. You should think about finding a metal box.

I like this idea. I am going to have to try it

Thank you

hi, is it possible to adapt a big bottle cooler into a curing chamber, to make biltong?

What I mean with adapt if its possible use the original fan, motor and compressor of this machines, cause they already come with a dehumidifing system and a thermostat!!

Thanks

Kind Regards

Ignacio

Since I don’t have luck trying to put hole in the side of the mini fridge which I cut the Freon tubing for the freezer compartment I don’t have any choice to dump this mini fridge. After watching your video in converting a mini wine cooler for a meat curing chamber, I have decided to convert a wine cooler for meat curing chamber. I HAVE A WIFI ITC-308-W(TEMP) AND A ICH-200-W( Humidity), can I USE THIS CONTROLLER INSTEAD OF THE STC-1000 ? Also, can I do the same procedure for thermostat parallel wiring. (shorting out the thermostat) I also notice in the picture of a PC FAN, what is the function of the fan, can you hook it with the ICH-200-W?

1win az basketbol mərcləri 1win az basketbol mərcləri

перепланировка проект перепланировка проект .

Покупка дипломов ВУЗов по всей Украине — с печатями, подписями, приложением и возможностью архивной записи (по запросу).

Документ максимально приближен к оригиналу и проходит визуальную проверку.

Мы гарантируем, что в случае проверки документа, подозрений не возникнет.

– Конфиденциально

– Доставка 3–7 дней

– Любая специальность

Уже более 999 клиентов воспользовались услугой — теперь ваша очередь.

На сайте — ответим быстро, без лишних формальностей.

Оформиление дипломов ВУЗов по всей Украине — с печатями, подписями, приложением и возможностью архивной записи (по запросу).

Документ максимально приближен к оригиналу и проходит визуальную проверку.

Мы гарантируем, что в случае проверки документа, подозрений не возникнет.

– Конфиденциально

– Доставка 3–7 дней

– Любая специальность

Уже более 4267 клиентов воспользовались услугой — теперь ваша очередь.

На сайте — ответим быстро, без лишних формальностей.

1win az apk yüklə https://www.1win3041.com

afdl brwmw kwd 1xbet afdl brwmw kwd 1xbet .

купить узи сканер http://www.kupit-uzi-apparat8.ru .

проект перепланировки квартиры для согласования проект перепланировки квартиры для согласования .

диплом купить в орле диплом купить в орле .

узи аппарат цена новый купить в россии http://www.kupit-uzi-apparat8.ru .

медицинское оборудование узи http://www.kupit-uzi-apparat9.ru .

заказать проект перепланировки квартиры в москве заказать проект перепланировки квартиры в москве .

тмг трансформатор тмг трансформатор .

Заказать диплом вы имеете возможность используя сайт компании. sciencenewhop.maxbb.ru/viewtopic.php?f=44&t=1318

[url=http://kupit-drova-kolotye-812.ru]kupit-drova-kolotye-812.ru[/url] .

1xbet 1xbet .

Недорогая инженерная доска inzenernay-doska1.ru .

сколько стоит аппарат узи цена http://www.kupit-uzi-apparat8.ru .

перепланировка проект перепланировка проект .

стоматология Архангельск запись стоматология Архангельск запись .

Оформиление дипломов ВУЗов по всей Украине — с печатями, подписями, приложением и возможностью архивной записи (по запросу).

Документ максимально приближен к оригиналу и проходит визуальную проверку.

Мы даем гарантию, что в случае проверки документа, подозрений не возникнет.

– Конфиденциально

– Доставка 3–7 дней

– Любая специальность

Уже более 3988 клиентов воспользовались услугой — теперь ваша очередь.

Сайт компании — ответим быстро, без лишних формальностей.

Hi! online pharmacy beneficial website.

tahmil la bah 888starz tahmil la bah 888starz .

узи аппараты цена http://www.kupit-uzi-apparat8.ru .

масляный трансформатор масляный трансформатор .

купить диплом вуза занесением реестр https://arus-diplom34.ru/ .

купить трансформатор силовой масляный трехфазный maslyanie-transformatory-kupit.ru .

Thanks for the article. Here’s more on the topic https://tonersklad.ru/

медицинский аппарат узи kupit-uzi-apparat10.ru .

аппарат ультразвуковой диагностики цена kupit-uzi-apparat9.ru .

Замковая инженерная доска Дуб в Декор Экспо. http://www.inzenernay-doska1.ru/ .

портативный узи сканер портативный узи сканер .

x bet x bet .

ТГ накрутка подписчиков ТГ накрутка подписчиков

Here’s more on the topic https://kinocirk.ru/

трансформаторы масляные http://www.maslyanie-transformatory-kupit.ru .

tasjil 888starz tasjil 888starz .

аппарат узи стоимость https://kupit-uzi-apparat9.ru/ .

я купил проведенный диплом я купил проведенный диплом .

купить новый узи аппарат купить новый узи аппарат .

1ex bet 1ex bet .

Напольная инженерная доска на кухню. https://inzenernay-doska1.ru/ .

аппарат узи для коров цена http://www.kupit-uzi-apparat10.ru .

Мы предлагаем дипломы любых профессий по приятным тарифам. Купить диплом педагогического института — kyc-diplom.com/diplom-articles/kupit-diplom-pedagogicheskogo-instituta.html

тмг цены https://www.maslyanie-transformatory-kupit.ru .

Мы предлагаем документы ВУЗов, расположенных на территории всей Российской Федерации. Заказать диплом любого университета:

купить аттестаты за 11 отзывы

купить трансформатор силовой масляный трехфазный купить трансформатор силовой масляный трехфазный .

мед аппарат узи https://www.kupit-uzi-apparat15.ru .

самая дешёвая свая ostankino-svai.ru .

школьный аттестат купить школьный аттестат купить .

виды аппаратов узи http://www.kupit-uzi-apparat9.ru .

инженерная доска Альянс паркет http://www.inzenernay-doska1.ru/ .

трансформаторы тмг http://www.maslyanie-transformatory-kupit.ru .

купить трансформаторы масляные купить трансформаторы масляные .

купить аппарат узи цены [url=kupit-uzi-apparat10.ru]купить аппарат узи цены[/url] .

1x 1x .

узи сканер купить узи сканер купить .

трансформатор масляный https://maslyanie-transformatory-kupit1.ru/ .

масляные трансформаторы купить maslyanie-transformatory-kupit.ru .

цена аппарата узи kupit-uzi-apparat9.ru .

melbet kz скачать https://melbet3002.com

аппарат узи цена в россии аппарат узи цена в россии .

bonus code 1win 2024 http://www.1win3046.com

1win original 1win original

melbet online casino melbet online casino

Hi there! pam pharma very good internet site.

аппарат узи стоимость аппарат узи стоимость .

thmyl aviator predictor 1xbet thmyl aviator predictor 1xbet .

melbet deposit options http://melbet3002.com/

трансформатор силовой купить maslyanie-transformatory-kupit2.ru .

1win casa de apuestas https://www.1win3048.com

Купить инженерную доску inzenernay-doska1.ru .

купить узи аппарат цена http://www.kupit-uzi-apparat9.ru/ .

купить трансформатор тмг https://www.maslyanie-transformatory-kupit.ru .

аттестат за 11 класс купить в братске аттестат за 11 класс купить в братске .

где можно купить аттестат за 11 класс адрес где можно купить аттестат за 11 класс адрес .

ramz tarwiji 888starz ramz tarwiji 888starz .

melbet .com https://melbet3002.com/

сколько стоит аппарат узи для людей цена kupit-uzi-apparat10.ru .

скачать melbet melbet https://melbet3002.com/

узи сканер купить москва https://kupit-uzi-apparat15.ru .

bonus code 1win 2024 https://www.1win3047.com

новые аппараты узи https://www.kupit-uzi-apparat9.ru .

купить аттестаты за 11 класс мурманск купить аттестаты за 11 класс мурманск .

масляный трансформатор купить масляный трансформатор купить .

1win casino oyunları 1win casino oyunları

1win cashback bonus 1win cashback bonus

1win aviator http://1win3037.com

аппарат узи цена в россии [url=http://www.kupit-uzi-apparat15.ru]аппарат узи цена в россии[/url] .

1win token https://www.1win3044.com

тмг http://maslyanie-transformatory-kupit1.ru .

one x bet one x bet .

1win online http://www.1win3047.com

инженерная доска Альянс паркет http://inzenernay-doska1.ru .

1win inscription 1win3046.com

1win lisenziyası http://1win3037.com

Hi! online pharmacy good website.

узи аппараты среднего класса kupit-uzi-apparat9.ru .

1win virtual idman https://1win3038.com/

узи оборудование цена узи оборудование цена .

трехфазный трансформатор масляный купить https://maslyanie-transformatory-kupit2.ru/ .

1win bonus 1win bonus

стоимость аппарата узи цена стоимость аппарата узи цена .

bono de casino 1win https://1win3045.com/

1win betting http://1win3045.com

bbruth 1win http://1win3048.com/

1win bonus code http://1win3044.com/

купить узи аппарат цена купить узи аппарат цена .

1win az giriş bloku http://1win3037.com/

масляные трансформаторы купить масляные трансформаторы купить .

888starz egypt 888starz egypt .

melbet промокод без депозита http://melbet3001.com/

мелбет официальный сайт войти https://www.melbet3001.com

стоимость масляного трансформатора http://maslyanie-transformatory-kupit2.ru/ .

сколько стоит узи аппарат https://www.kupit-uzi-apparat9.ru .

1win app 1win3047.com

силовой тмг http://maslyanie-transformatory-kupit1.ru .

1win az promo ilə qeydiyyat https://1win3037.com/

1win casino en línea http://www.1win3044.com

купить аппарат узи цены новый http://kupit-uzi-apparat10.ru/ .

1win az http://1win3038.com/

Hello! buy ed drugs pills great internet site.

1win az canlı mərclər http://www.1win3037.com

купить аттестат за 11 классов вечерней школы купить аттестат за 11 классов вечерней школы .

1win qeydiyyat zamanı bonus http://1win3043.com

узи аппарат купить цена http://www.kupit-uzi-apparat9.ru .

1win promo kodu necə daxil etməli 1win promo kodu necə daxil etməli

где купить узи аппарат http://www.kupit-uzi-apparat10.ru .

масляный трансформатор купить http://www.maslyanie-transformatory-kupit2.ru .

1win партнер http://www.1win3047.com

купить диплом с занесением в реестр в уфе https://arus-diplom31.ru/ .

1win az giriş https://www.1win3043.com

доставка воды на дачу цистерна цена http://www.dostavka-tehnicheskoi-vodi.ru .

aviator 1win http://www.1win3046.com

ставки на спорт аналитика прогнозы http://www.stavki-na-sport-prognozy.ru .

трехфазный трансформатор масляный купить http://www.maslyanie-transformatory-kupit2.ru .

мелбет ру melbet3001.com

купить аттестат 10 11 класс в красноярске купить аттестат 10 11 класс в красноярске .

тмг maslyanie-transformatory-kupit1.ru .

1win apk android 1win3046.com

купить диплом о высшем образовании с занесением в реестр владивосток https://www.arus-diplom35.ru .

скачат мелбет http://melbet3002.com

аппарат узи стоимость оборудования http://kupit-uzi-apparat10.ru .

трансформатор тм http://www.maslyanie-transformatory-kupit.ru .

1win daxil ol https://www.1win3043.com

скачать мелбет с 1xgames скачать мелбет с 1xgames

купить узи аппарат цена купить узи аппарат цена .

1win партнерка отзывы 1win партнерка отзывы

melbet kz скачать http://melbet3001.com

купить трансформатор силовой масляный трехфазный maslyanie-transformatory-kupit1.ru .

888starz agent 888starz agent .

melbet партнерская программа http://melbet3001.com/

техническая вода с доставкой https://dostavka-tehnicheskoi-vodi.ru/ .

Hello! order ed drugs beneficial internet site.

лига ставок прогнозы http://www.stavki-na-sport-prognozy.ru .

аппарат узи цена в россии новый http://www.kupit-uzi-apparat10.ru .

1win depozit bonusu http://1win3043.com

диплом купить москва диплом купить москва .

1win mexico https://www.1win3046.com

1win qeydiyyat necə olur https://www.1win3043.com

1win mx https://www.1win3044.com

melbet букмекерская кантора http://melbet3001.com

прогнозы на ставки http://www.stavki-na-sport-prognozy.ru/ .

доставка технической воды спб dostavka-tehnicheskoi-vodi.ru .

тмг цены http://www.maslyanie-transformatory-kupit.ru/ .

casino en 1 win https://www.1win3046.com

портативный узи сканер купить портативный узи сканер купить .

где можно купить аттестат 11 где можно купить аттестат 11 .

1win descargar https://1win3044.com/

download melbet app https://www.melbet3002.com

каталог трансформаторов каталог трансформаторов .

купить диплом с реестром о высшем образовании купить диплом с реестром о высшем образовании .

техническая водадоставка технической воды http://dostavka-tehnicheskoi-vodi.ru/ .

Добавить подписчиков в Телеграм канал Добавить подписчиков в Телеграм канал

Getting it sane, like a demoiselle would should

So, how does Tencent’s AI benchmark work? Prime, an AI is confirmed a shining reprove from a catalogue of closed 1,800 challenges, from construction figures visualisations and интернет apps to making interactive mini-games.

Post-haste the AI generates the arrangement, ArtifactsBench gets to work. It automatically builds and runs the mould in a shut and sandboxed environment.

To upwards how the haunt behaves, it captures a series of screenshots ended time. This allows it to interrogate respecting things like animations, avow changes after a button click, and other unmistakeable consumer feedback.

Conclusively, it hands to the school all this asseverate – the autochthonous solicitation, the AI’s encrypt, and the screenshots – to a Multimodal LLM (MLLM), to face as a judge.

This MLLM adjudicate isn’t tow-headed giving a undecorated философема and as contrasted with uses a particularized, per-task checklist to armies the d‚nouement upon across ten selected metrics. Scoring includes functionality, purchaser working swain heartthrob obligation, and unaffiliated aesthetic quality. This ensures the scoring is respected, in conformance, and thorough.

The efficacious discuss is, does this automated beak sic deserve careful taste? The results nudge it does.

When the rankings from ArtifactsBench were compared to WebDev Arena, the gold-standard aura where bona fide humans философема on the unexcelled AI creations, they matched up with a 94.4% consistency. This is a elephantine sudden from older automated benchmarks, which solely managed hither 69.4% consistency.

On unnerve prat of this, the framework’s judgments showed at an unoccupied 90% unanimity with competent perchance manlike developers.

https://www.artificialintelligence-news.com/

tanzil tatbiq 888starz tanzil tatbiq 888starz .

melbet bonus http://melbet3002.com/

купить трансформатор тмг https://maslyanie-transformatory-kupit.ru .

сколько стоит узи аппарат сколько стоит узи аппарат .

стоимость масляного трансформатора http://www.maslyanie-transformatory-kupit2.ru .

трансформатор масляный http://www.maslyanie-transformatory-kupit1.ru .

1win 1win

тмг трансформатор тмг трансформатор .

масляный трансформатор http://www.maslyanie-transformatory-kupit.ru .

ультразвуковой диагностический аппарат ультразвуковой диагностический аппарат .

доставка технической воды водовозом https://www.dostavka-tehnicheskoi-vodi.ru .

ставки и прогнозы букмекеров на футбол сегодня http://stavki-na-sport-prognozy.ru/ .

ставки ру stavki-na-sport-prognozy2.ru .

трансформаторы тмг http://maslyanie-transformatory-kupit1.ru .

Thanks for the article. Here’s more on the topic https://l-spb.ru/

масляные трансформаторы http://maslyanie-transformatory-kupit.ru/ .

1win lisenziyası http://www.1win3043.com

ультразвуковой аппарат цена ультразвуковой аппарат цена .

техвода https://dostavka-tehnicheskoi-vodi.ru/ .

1xBet — это одна из самых популярных и надежных платформ, которая предлагает уникальные возможности и привлекательные бонусы для своих пользователей. Независимо от того, являетесь ли вы новичком в мире ставок или опытным игроком, 1xBet промокод 2025, воспользуйтесь бонусным промокодом, чтобы получить бесплатный приветственный бонус в размере 100%. При регистрации введите данный код и получите бонус до 32 500 рублей (или эквивалент в другой валюте до 130$).

melbet download iphone melbet3002.com

прогнозы на сегодня http://www.stavki-na-sport-prognozy.ru/ .

Hi! buy ed drugs medication great web site.

купить легально диплом [url=arus-diplom35.ru]купить легально диплом[/url] .

аттестат купить 9 класс аттестат купить 9 класс .

Заказать диплом о высшем образовании поспособствуем. Купить диплом специалиста Орёл – diplomybox.com/kupit-diplom-spetsialista-v-orle

трансформатор тмг трансформатор тмг .

где купить аттестат за 11 класс в череповце где купить аттестат за 11 класс в череповце .

как вывести деньги с melbet melbet3001.com

мелбет сайт https://www.melbet3001.com

прогнощы http://stavki-na-sport-prognozy2.ru/ .

1win deposit http://1win3046.com

como retirar en 1win http://1win3048.com

1win affiliate login https://www.1win3046.com

1win affiliation http://1win3045.com/

трансформатор тмг трансформатор тмг .

melbet plinko https://www.melbet3002.com

Оформиление дипломов ВУЗов по всей Украине — с печатями, подписями, приложением и возможностью архивной записи (по запросу).

Документ максимально приближен к оригиналу и проходит визуальную проверку.

Мы гарантируем, что в случае проверки документа, подозрений не возникнет.

– Конфиденциально

– Доставка 3–7 дней

– Любая специальность

Уже более 1865 клиентов воспользовались услугой — теперь ваша очередь.

Купить диплом Украина — ответим быстро, без лишних формальностей.

Покупка дипломов ВУЗов по всей Украине — с печатями, подписями, приложением и возможностью архивной записи (по запросу).

Документ максимально приближен к оригиналу и проходит визуальную проверку.

Мы даем гарантию, что в случае проверки документа, подозрений не возникнет.

– Конфиденциально

– Доставка 3–7 дней

– Любая специальность

Уже более 3723 клиентов воспользовались услугой — теперь ваша очередь.

Уточнить здесь — ответим быстро, без лишних формальностей.

Покупка дипломов ВУЗов по всей Украине — с печатями, подписями, приложением и возможностью архивной записи (по запросу).

Документ максимально приближен к оригиналу и проходит визуальную проверку.

Мы гарантируем, что в случае проверки документа, подозрений не возникнет.

– Конфиденциально

– Доставка 3–7 дней

– Любая специальность

Уже более 2437 клиентов воспользовались услугой — теперь ваша очередь.

Узнать условия — ответим быстро, без лишних формальностей.

videos 1win https://1win3046.com

download 1win download 1win

que es 1win que es 1win

videos 1win http://1win3046.com

масляный трансформатор масляный трансформатор .

Быстро и просто приобрести диплом об образовании!

Мы можем предложить дипломы психологов, юристов, экономистов и любых других профессий по разумным тарифам— kubmat.ru

casino online 1win http://1win3048.com

ставки прогноз ставки прогноз .

Мы предлагаем оформление дипломов ВУЗов В киеве — с печатями, подписями, приложением и возможностью архивной записи (по запросу).

Документ максимально приближен к оригиналу и проходит визуальную проверку.

Мы гарантируем, что в случае проверки документа, подозрений не возникнет.

– Конфиденциально

– Доставка 3–7 дней

– Любая специальность

Уже более 3261 клиентов воспользовались услугой — теперь ваша очередь.

Открыть — ответим быстро, без лишних формальностей.

1win x https://www.1win3047.com

app 888starz app 888starz .

descargar 1win http://www.1win3044.com

casino en 1 win http://1win3046.com/

1win http://www.1win3044.com

dostavka-drov-na-dachu-812.ru .

ставкипрогнозы http://stavki-na-sport-prognozy1.ru .

Покупка дипломов ВУЗов по всей Украине — с печатями, подписями, приложением и возможностью архивной записи (по запросу).

Документ максимально приближен к оригиналу и проходит визуальную проверку.

Мы даем гарантию, что в случае проверки документа, подозрений не возникнет.

– Конфиденциально

– Доставка 3–7 дней

– Любая специальность

Уже более 3677 клиентов воспользовались услугой — теперь ваша очередь.

Купить диплом о высшем образовании — ответим быстро, без лишних формальностей.

Мы предлагаем оформление дипломов ВУЗов по всей Украине — с печатями, подписями, приложением и возможностью архивной записи (по запросу).

Документ максимально приближен к оригиналу и проходит визуальную проверку.

Мы даем гарантию, что в случае проверки документа, подозрений не возникнет.

– Конфиденциально

– Доставка 3–7 дней

– Любая специальность

Уже более 3819 клиентов воспользовались услугой — теперь ваша очередь.

Здесь — ответим быстро, без лишних формальностей.

ставки и прогнозы ставки и прогнозы .

androide mostbet indir androide mostbet indir .

1win affiliates https://1win3048.com

1win az qeydiyyat 1win az qeydiyyat

melbet фрибет https://www.melbet3001.com

Доставка в любые российские регионы и другие страны https://sinapple.ru/collection/kremy-dlya-litsa/product/keenwell-oxidance-crema-antioxidante-regeneradora-noche-vit-cc

Какие дни благоприятны для стрижки и салонных уходовых процедур, а в какие лучше воздержаться от посещения парикмахера? Рассказываем!

доставка воды на стройку https://dostavka-tehnicheskoi-vodi.ru/ .

прогнозы ставок http://www.stavki-na-sport-prognozy.ru/ .

прогнозы прогнозы .

проверить купон мелбет http://www.melbet3002.com

melbet game download melbet game download

купить трансформаторы масляные http://www.maslyanie-transformatory-kupit1.ru/ .

ставки и прогнозы на спорт http://stavki-na-sport-prognozy.ru .

bonificacion de casino 1win https://1win3045.com

1win jetx http://1win3048.com/

1win android http://1win3048.com/

привозная вода цена за куб http://dostavka-tehnicheskoi-vodi.ru/ .

melbet игровые автоматы melbet игровые автоматы

трансформатор тм maslyanie-transformatory-kupit1.ru .

ставка прогноз http://stavki-na-sport-prognozy.ru .

прогноз ставок прогноз ставок .

code bonus 1win https://1win3047.com

1win mobil qeydiyyat https://1win3043.com/

прогноз ставки на спорт http://www.stavki-na-sport-prognozy1.ru .

mines pro 1win mines pro 1win

melbet зеркало 2020 https://melbet3001.com

как пополнить счет на melbet как пополнить счет на melbet

plinko 1win https://1win3047.com

1win az aviator strategiya 1win3043.com

melbet скачать apk https://melbet3003.com/

ставки прогнозы https://www.stavki-na-sport-prognozy.ru .

1win az casino 1win az casino

перевозка воды http://dostavka-tehnicheskoi-vodi.ru/ .

Мы предлагаем оформление дипломов ВУЗов В киеве — с печатями, подписями, приложением и возможностью архивной записи (по запросу).

Документ максимально приближен к оригиналу и проходит визуальную проверку.

Мы даем гарантию, что в случае проверки документа, подозрений не возникнет.

– Конфиденциально

– Доставка 3–7 дней

– Любая специальность

Уже более 2538 клиентов воспользовались услугой — теперь ваша очередь.

Купить дипломы о высшем — ответим быстро, без лишних формальностей.

mel bet kz https://www.melbet3007.com

Оформиление дипломов ВУЗов В киеве — с печатями, подписями, приложением и возможностью архивной записи (по запросу).

Документ максимально приближен к оригиналу и проходит визуальную проверку.

Мы даем гарантию, что в случае проверки документа, подозрений не возникнет.

– Конфиденциально

– Доставка 3–7 дней

– Любая специальность

Уже более 3982 клиентов воспользовались услугой — теперь ваша очередь.

Можно ли купить диплом о высшем образовании — ответим быстро, без лишних формальностей.

ставка на спорт прогнозы stavki-na-sport-prognozy2.ru .

1win idman mərcləri https://1win3043.com

1win az apk yüklə http://www.1win3043.com

Hello! usa non peescription pharmacy good website.

прогноз на спорт на сегодня от профессионалов http://prognozy-na-sport-2.ru/ .

melbet sports live melbet3007.com

техническая вода цена dostavka-tehnicheskoi-vodi.ru .

высокопроходимые прогнозы на спорт высокопроходимые прогнозы на спорт .

бк мелбет официальный сайт зеркало https://www.melbet3003.com

скачать мелбет зеркало http://melbet3003.com

melbet скачать 2023 http://melbet3007.com

melbet баланс 500 рублей http://www.melbet3003.com

жб прогнозы на футбол сегодня http://www.prognozy-na-futbol-1.ru/ .

Thanks for the article. Here is a website on the topic – https://kanunnikovao.ru/

прогноз букмекеров на сегодня http://www.stavki-na-sport-prognozy.ru .

mostbet az virtual oyunlar mostbet az virtual oyunlar

melbet ios app melbet ios app

1win партнерка 1win партнерка

спорт прогнозы на спорт от профессионалов бесплатно http://prognozy-na-sport-3.ru .

melbet вход 2019 https://melbet3007.com/

техническая вода цена https://dostavka-tehnicheskoi-vodi.ru .

прогнозы ставки http://stavki-na-sport-prognozy.ru .

прогнозы на сегодня [url=https://www.stavki-na-sport-prognozy2.ru]прогнозы на сегодня[/url] .

cuenta de bonificación del casino 1win http://1win3045.com/

melbet sports live melbet3007.com

мелбет бонусный счет http://melbet3005.com/

купить аттестат за 11 класс рязань http://www.arus-diplom21.ru/ .

прогнозы на спорт с высокой проходимостью бесплатно с большим коэффициентом http://www.prognozy-na-sport-2.ru .

прогноз ставка http://www.stavki-na-sport-prognozy1.ru .

точный прогнозы на футбол http://www.prognozy-na-futbol-1.ru .

доставка технической воды спб dostavka-tehnicheskoi-vodi.ru .

прогнозы по ставкам http://www.stavki-na-sport-prognozy2.ru .

я купил диплом с проводкой я купил диплом с проводкой .

mostbet az aviator strategiya mostbet4055.ru

прогнозы и ставки на спорт http://prognozy-na-sport-3.ru .

точный прогнозы на футбол http://www.prognozy-na-futbol-2.ru .

1win ios http://1win3045.com

Hi there! online us pharmacies great internet site.

1win partners 1win partners

спорт прогнозы от профессионалов [url=prognozy-na-sport-2.ru]prognozy-na-sport-2.ru[/url] .

продажа пластиковых окон в москве rem-okoshko.ru .

корочки для аттестата купить за 11 класс корочки для аттестата купить за 11 класс .

промокоды на мелбет melbet3003.com

точные прогнозы на футбол сегодня бесплатно http://www.prognozy-na-futbol-1.ru/ .

mostbet site oficial baixar mostbet site oficial baixar .

ставки прогнозы на спорт http://stavki-na-sport-prognozy2.ru/ .

спорт прогнозы бесплатно http://prognozy-na-sport-3.ru/ .

mostbet pul çıxarma http://mostbet4055.ru

ближайшие прогнозы на спорт https://prognozy-na-sport-2.ru/ .

ставки на спорт ставки на спорт .

прогнозы на футбол prognozy-na-futbol-1.ru .

Thanks for the article. Here’s more on the topic mirka-master.ru .

купить диплом с проводкой моих купить диплом с проводкой моих .

дома под ключ московская область каркас дома под ключ московская область каркас .

bonus code 1win 2024 http://1win3045.com

аналитика ставок на спорт http://www.stavki-na-sport-prognozy2.ru .

прогноз на футбол на сегодня от профессионалов https://prognozy-na-futbol-2.ru .

ставки на спорт прогнозы бесплатно http://prognozy-na-sport-2.ru/ .

точные прогнозы на спорт точные прогнозы на спорт .

где купить аттестаты за 11 класс с занесением в реестр отзывы где купить аттестаты за 11 класс с занесением в реестр отзывы .

прогноз ставок на футбол http://www.prognozy-na-futbol-1.ru .

мелбет официальный сайт http://www.melbet3004.com

высокоточные прогнозы на спорт http://prognozy-na-sport-1.ru/ .

прогноз ставок на сегодня прогноз ставок на сегодня .

прогнозы prognozy-na-sport-3.ru .

промокод мелбет 2024 https://melbet3003.com/

прогноз букмекеров на сегодня https://stavki-na-sport-prognozy1.ru .

самые точные прогнозы на хоккей prognozy-na-khokkej-segodnya.ru .

1win bono de bienvenida 1win bono de bienvenida

1win casino online http://1win3045.com/

melbet kz промокод melbet kz промокод

точные прогнозы на спорт от экспертов бесплатно на сегодня https://www.prognozy-na-sport-2.ru .

прогноз ставок на футбол https://prognozy-na-futbol-2.ru/ .

Оформиление дипломов ВУЗов по всей Украине — с печатями, подписями, приложением и возможностью архивной записи (по запросу).

Документ максимально приближен к оригиналу и проходит визуальную проверку.

Мы гарантируем, что в случае проверки документа, подозрений не возникнет.

– Конфиденциально

– Доставка 3–7 дней

– Любая специальность

Уже более 2495 клиентов воспользовались услугой — теперь ваша очередь.

Купить срочно диплом о высшем образовании вуза — ответим быстро, без лишних формальностей.

прогноз на футбол prognozy-na-futbol-1.ru .

мелбет офшор http://melbet3005.com/

экспресс прогнозы на спорт экспресс прогнозы на спорт .

mostbet apps download mostbet apps download .

melbet зеркало http://melbet3005.com/

прогноз на спорт сегодня бесплатно http://www.prognozy-na-sport-2.ru .

888starz kirish 888starz kirish .

мелбет. ру https://melbet3004.com/

прогнозы и ставки на спорт http://prognozy-na-sport-3.ru/ .

прогнозы на футбол https://prognozy-na-futbol-1.ru .

ставки на футбол сегодня http://www.prognozy-na-futbol-2.ru .

melbet uk http://melbet3007.com

аттестат 9 11 купить аттестат 9 11 купить .

бесплатные прогнозы на хоккей http://www.prognozy-na-khokkej-segodnya.ru .

melbet скачать апк melbet3005.com

самые точные прогнозы на спорт от профессионалов http://www.prognozy-na-sport-3.ru .

прогнозы ставки на спорт прогнозы ставки на спорт .

экспресс на футбол сегодня https://www.prognozy-na-futbol-2.ru .

mostbet hesab yaratmaq http://mostbet4055.ru/

лучшие прогнозы на хоккей лучшие прогнозы на хоккей .

mostbet uz tennis tikish https://www.mostbet4072.ru

все про спорт прогнозы http://prognozy-na-sport-1.ru/ .

мелбет фрибет за регистрацию melbet3005.com

мелбет мини игры melbet3007.com

онлайн оценка наручных часов http://www.ocenka-chasov-onlajn8.ru .

прогноз ру https://www.stavki-na-sport-prognozy1.ru .

мелбет казахстан http://melbet3007.com

ставки на хоккей http://www.prognozy-na-khokkej-segodnya.ru .

mostbet depozit bonusu https://mostbet4055.ru

мосбкт мосбкт

mostbet az promo kod http://mostbet4055.ru

mostbet aviator demo https://www.mostbet4055.ru

точный прогнозы на футбол http://www.prognozy-na-futbol-2.ru/ .

support melbet support melbet

melbet зеркало рабочее на сегодня http://www.melbet3005.com

условия бонуса в мелбет http://melbet3003.com/

скачать бк 888starz скачать бк 888starz .

melbet скачать 2023 http://melbet3004.com

1win app download 1win3044.com

ставки на хоккей ставки на хоккей .

ставки на хоккей на сегодня prognozy-na-khokkej-segodnya.ru .

стопроцентные прогнозы на спорт https://prognozy-na-sport-1.ru .

точные прогнозы на футбол сегодня бесплатно точные прогнозы на футбол сегодня бесплатно .

melbet roulette melbet roulette

1win casino en línea http://1win3044.com

прогнозы на ставки прогнозы на ставки .

ставки букмекеров на хоккей http://www.prognozy-na-khokkej-segodnya.ru/ .

melbet официальный сайт скачать бесплатно http://melbet3007.com/

прогноз хоккей прогноз хоккей .

прогноз ставок на футбол https://prognozy-na-futbol-2.ru .

мелбет бк отзывы https://melbet3005.com

официальный сайт melbet http://www.melbet3007.com

оценка часов онлайн по фото http://www.ocenka-chasov-onlajn8.ru/ .

mostbet shaxsiy http://www.mostbet4072.ru

прогноз на футбол сегодня https://www.prognozy-na-futbol-1.ru .

Рейтинг товара по оценке пользователей.

Высота подъёма: 280-900 мм.

Низкопрофильный подъемный стол OX NY-100 Low опускается почти до уровня пола, не требуя установки в приямок.

Высота подъема до 3 м. Грузоподъемность до 50000 кг. Размеры индивидуально Скорость подъема от 0,13 м/с.

https://energo-pole.ru/skladskaya-tekhnika/shtabelery/elektroshtabelery/elektricheskie-shtabelery-s-ploshchadkoy/ps16n5500/

грузовые манипуляторы.

Столы с одинарными ножницами.

прогнозы на сегодня спорт https://prognozy-na-sport-2.ru/ .

888starz uz skachat 888starz uz skachat .

бесплатные точные прогнозы https://prognozy-na-sport-1.ru/ .

лайв прогнозы на спорт лайв прогнозы на спорт .

melbet скачать апк melbet скачать апк

футбол прогноз на сегодня prognozy-na-futbol-2.ru .

melbet apk télécharger gratuit https://www.melbet3003.com

точные прогнозы на футбол сегодня бесплатно prognozy-na-futbol-1.ru .

прогноз на хоккей прогноз на хоккей .

косметический ремонт квартиры под ключ косметический ремонт квартиры под ключ .

прогноз на хоккей https://www.prognozy-na-khokkej-segodnya.ru .

mostbet link mostbet link

прогнозы от профессионалов http://www.prognozy-na-sport-1.ru/ .

kupit-suhie-drova-812.ru .

оценить часы в москве http://ocenka-chasov-onlajn9.ru/ .

хоккей прогноз на сегодня prognozy-na-khokkej-segodnya1.ru .

прогноз на хоккей на сегодня http://prognozy-na-khokkej-segodnya.ru/ .

точные прогнозы на футбол сегодня бесплатно http://www.prognozy-na-futbol-1.ru/ .

почему не работает мелбет http://melbet3007.com/

прогнозы ставки на спорт прогнозы ставки на спорт .

прогнозы на спорт онлайн http://www.prognozy-na-sport-2.ru .

Мы предлагаем документы ВУЗов, которые расположены в любом регионе России. Приобрести диплом любого ВУЗа:

купить аттестат за 11 класс в хабаровске

starz 888 starz 888 .

прогнозы на спорт от профессионалов точные бесплатно на сегодня https://prognozy-na-sport-3.ru .

Заказать диплом вы имеете возможность через сайт компании. jobs.colwagen.co/employer/education-ua

promokod melbet promokod melbet

онлайн ломбард часов http://www.ocenka-chasov-onlajn8.ru/ .

прогноз на сегодня футбол http://www.prognozy-na-futbol-1.ru .

mostbet latest version mostbet latest version .

mostbet qeydiyyat pulsuz mostbet qeydiyyat pulsuz

melbet tj скачать https://melbet3003.com

купить диплом в ульяновске купить диплом в ульяновске .

ставки футбол http://www.prognozy-na-futbol-2.ru .