This Homemade Salami recipe appears on page 183 of Michael Ruhlman’s amazing adventure, Charcuterie. It is his Tuscan Salami recipe that I transcribed for the amount of pork I had. I bought 2 pounds of pork shoulder and told the butcher it was for sausage. I agreed with his suggestion of a 70/30 lean-to-fat mix. Once I got it home, I weighed it in grams to figure out my recipe. This is basically MR’s recipe (0.4x):

- 900g pork

- 20g salt

- 2.5g Instacure #2

- 8g Bactoferm (http://www.butcher-packer.com)

- 24g water

- 24g Dextrose

- 1/4 c red wine

- 5g fennel

- 5g pepper

- 1t garlic powder

Step One: Soak the casings

Pork middles are natural casings that come slightly dried and packed in a lot of salt. Soak them in a bowl of cold water for an hour. Running the tap and holding the end open under the stream of water will give the insides a good rinse, too. Use lots of water. These guys are salty!

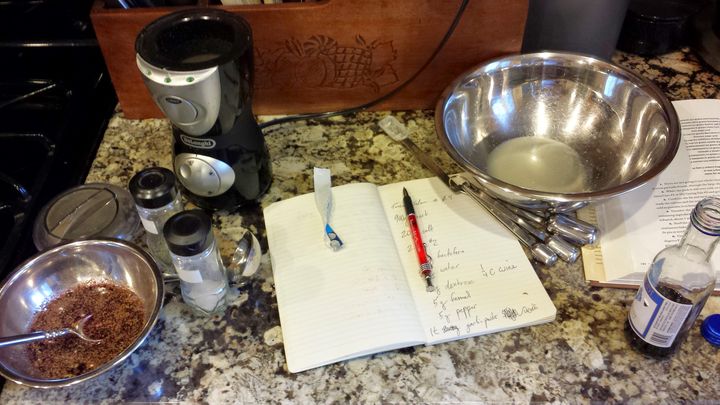

Mise en place

Measure out your spices. I prefer whole spices that I can grind myself. That’s why the spice quantities are in grams. You can also suit your own tastes about how big the spice bits are in the finished product.

Rehydrate the Bactoferm in a little warm water. Stay away from that tap! Bottled water only! The chlorine in tap water will kill the mold you just dropped $15 on! Mix together the wine and the spices. I always write down my figures as I scale a recipe. I almost added the full amount of salt to my spice bowl. Measure twice, cut once is an old carpenter’s adage that I still use.

Grinding

Chill the removable grinder parts in the freezer until very cold. In fact, everything should be very cold when making salami. You want the fat in the finished product to be autonomous, not smeared into the lean. Start with the fat half-frozen, if you can. Grind into a cold bowl. Everything should be very CLEAN when making homemade salami. Salami is fermenting while it dries. You don’t want random stray microbes adding off-tastes to your prize-winning salami.

Mixing

Add everything to the mixer bowl (that you had in the freezer, right?). Give the filling a good spin for not more than a minute and then back into the freezer while you reassemble the grinder with the finer cutting disk and the stuffer tube.

Stuffing!

Now the fun part: stuffing. Run the cold mix through the grinder again with the stuffing tube that’s been loaded up with the casings. Keep the casings as wet as you can or they’ll stick to the tube.

I like to put a piece of plastic wrap over the ice in my landing area. It prevents the ice from sticking to the casings and tearing them. Don’t forget to perforate the casings. Just use a large sterile sewing needle to poke lots of holes in the casing. This helps to allow the sausages to dry evenly and to release any air bubbles that occurred during stuffing.

Ready to go in the curing box! Just like my other recipes, these will spend the next few weeks in the meat curing cabinet. One of these days I promise a tour of the curing chest. Stay tuned!

Things that make no sense to me:

There’s no sugar, and no ferment. I don’t understand why one wouldn’t ferment. To me, a good ferment is the difference between salami and a dried sausage.

So much grinding! This is certainly arguable, and many disagree, but I so much prefer a single large or largish grind.

On a related note, as many point out, those casings are tiny. You’re not going to get the character that comes from drying meat. You’re just going to get dried out meat. I’m a beef middle guy, but that’s mostly because that’s where I have the most experience, and they make for some nice salami…

Why the ice post stuff? Next step is into your drying room, right? Why bother trying to keep them cold?

(Also I hate garlic powder with a passion that will not fade, but that doesn’t really have anything to do with salami…)

onioning, Thanks for the comments! A couple of clarifications for you. Dextrose is sugar. It’s been recommended in Ruhlman for feeding the Bactoferm.

Reread the grinding section. I guess I wasn’t clear on keeping the fat cold so it doesn’t melt into the meat.

I am taking to heart all the comments about my tiny casings. Thank you for tipping the balance and bringing me over. I bought a package of 61mm Fibrous Protein-Lined Casings for the next batch.

Oh, and here’s the cure box: https://www.betterdoneyourself.com/2014/05/15/diy-meat-curing-chamber/

In cooking school, I had a french chef tell me of the horrors of the amount of E. coli that occurs on raw garlic and to never use in raw in fermented products. As I write this, I think I need to revisit my dill pickling technique…

Dextrose is unfermentable sugar. One uses it because they want sweetness that won’t ferment away. Ordinarily one uses regular table sugar to feed the bactoferm.

It wasn’t clear from your post if you are fermenting these. It sounds like they go straight from stuffing into your drying chamber. Not gonna get a lot of fermenting that way.

Sure. Any raw vegetable product can contain E- Coli. Your meat could too. If you’re really worried, you can blanch your produce first, though obviously this changes the taste of things. You don’t need to fully cook anything, just heat the surface temp over 180 or so. Personally (and professionally), the risk of something like raw garlic having E. Coli is low enough that I’m not worried (nor is the USDA). It may be that a proper ferment mitigates this issue. I don’t recall how E. Coli holds up to high acidity, but IIRC a low pH is an effective barrier to E. Coli. When I make a salami, the pH gets below 4.3. Similarly, in your dill pickling case, the acidity is way more than sufficient. I suppose it’s an issue with non-fermented salami, but the lack of ferment presents other issues as well. If you want a fully safe product, drop the pH via ferment, and dry until the aW is low enough.

“Dextrose is unfermentable sugar. One uses it because they want sweetness that won’t ferment away. Ordinarily one uses regular table sugar to feed the bactoferm.”

That’s so wrong it hurts. If you’re going to give advice, you should really understand what you are talking about.

Dextrose is used in salami precisely because it is EASILY FERMENTABLE sugar. It’s sole purpose in salami is to feed the starter cultures. Anyone with any type of salumi knowledge would tall you this. 0.5%—0.75% dextrose is the average, with most preferring 0.%.

Get your shit straight, man.

Pingback: Salami Failure - Better Done Yourself

Pingback: Salami Failure - Better Done Yourself

Thanks for sticking up for me, Kyle! I really DID do my homework…

Pingback: Salami Binder Failure - Better Done Yourself

so much superb info on here, : D.

Giuseppe Zanotti http://www.giuseppeszanotti.com