Soapmaking is an ancient art. You can make your own at home with some very basic ingredients. I usually do a hot process soap which is one that you cook in the pot after you mix together the fat and the lye. But, I’m getting ahead of myself. Let’s start at the beginning.

Soap is a mixture of lye and fat. If properly balanced, the mixture will be pH neutral. When you mix together an acid and a base, you get salt. When you mix together fat and a base, you get soap! To get this to work, you’ll need to know the chemical properties of the fats that you’re using. This is easily found on the Internet in the form of “soap calculators”. My favorite is Soap Calc. Basically, all you need to do is enter the type of fats that you want to use and hit calculate. Soap Calc will tell you the properties of the finished soap, like how well it will clean or how sudsy it will be. Soap Calc will also tell you exactly how much lye to use.

For my soap, I wanted to use mostly tallow (beef fat). So I plugged in the weight of the tallow I had into Soap Calc. Then, I added 16oz of Castor Oil (for suds) and 16oz of Coconut Oil (for conditioning), and finally 8 oz of Olive Oil (for cleansing). Soap Calc figured on 12.1 oz of lye and 32 oz of water.

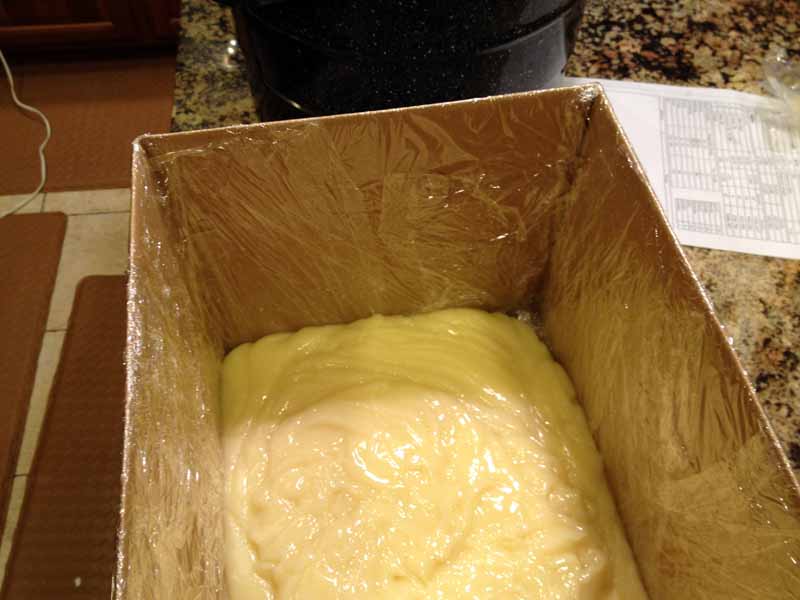

First things first! Make a mold! Get this ready before you mix anything. I used a sturdy box that I lined with plastic wrap. You can also use a length of PVC pipe from the hardware store that’s been lubed up on the inside and one end covered with plastic wrap.

Pour your fats into a large pot and slowly raise the heat to melt. Meanwhile, get the Lye ready.

Mixing Lye and water is DANGEROUS. Always pour the lye into the water. Pouring water into lye could potentially create an explosive reaction. I wore my goggles and my rubber gloves. Keep a big bottle of vinegar nearby to douse lye burns on your skin. Do your mixing in a large Pyrex bowl. This WILL give off a fair amount of heat and noxious fumes. Do it outside!

Once the Lye is dissolved, you can slowly pour it all into the fat pot and start stirring. Try to get the temp of the fat to be as close to the temp of the hot bowl of lye solution as you can. Neither one NEED to be very hot, but just close.

Be careful with the mixing process. Remember, you’ve got lye in that pot. I usually switch over to a stick/immersion blender when my arm gets tired. Stirring by hand can take up to an hour, depending on the temperature of your mix. After about 10 minutes with the immersion Blender, you should have a very homogeneous mass.

Keep stirring until the liquid traces, or leaves tracks in the mix as you move your stirrer around.

Use a rubber scraper to make sure you’ve got everything incorporated and give it a few final good stirs. Pour the whole mess into your mold and spread with the scraper.

Let this sit overnight. Wrap it with a blanket. This process of the lye and the fat mixing and neutralizing one another takes about 24 hours. It works better if it’s not losing heat at the same time.

After 24 hours, unwrap it and leave it out on a wire rack for about 6 weeks. During this time, the soap will harden and finish up the neutralization process. After the first week, you can cut and shape it into bars, before it gets too hard.

Scrape off a little piece of your soap and test it. Put it in a clean jar with some warm water and give it a good shake. Suds? cool… soap. Old-timers used to check to see if the soap was balanced by tasting it. Don’t eat it, but give it a little lick. Does it taste like soap or does it make your tongue tingle? Tingle is bad. Tingle is unbalanced lye. You’re going to have to start over…

Otherwise, you’ve made some great soap! It’s got all its natural glycerine intact. The lye is gone and has created a wonderful bath bar through the process of saponification! Yes, that’s a real word. Google it!

UPDATE!

I cut the soap this weekend! It seems a little moist and sticky to me, but this is my first batch of cold process soap. I used a cheese wheel slicer to make the bars, and then cut them all in half again to make thin bars. I put them all on a coated wire rack and into the loft to dry and cure a little longer. The soap cleans great. It’s just a little soft. –Like when you leave your soap bar in a little water in the soap dish and it gets soft and rinses away too fast as you use it.

Wow- this recipe does not sound tasty but it sure sounds like it makes great SOAP. John, how and when do you add fragrance? Is an oil-based type best?

I added essential oil right before I poured it into the mold. Good essential oil should be used in the ratio of 1/2 oz to 1 pound of fat/oil. I used 3/4 lavender oil and 1/4 tea tree oil. The slab is curing in the freezer / vinegar room. It smells amazing! No one’s noticed the vinegar smell from the other things curing in there, yet!

Ahhhhh- thanks for the clarification!

I don’t know if this is a silly question or not, since I am new to soap making. Can you use your bowls and immersion blender again for your “regular” cooking or do you really need to keep these strictly for soap making?

You can use all your regular cookware. The lye solution is best made in plastic, as sodium hydroxide will eat through metal. The best part is that clean up is easy because you’re just rinsing off soap!